Glass

Laminated Glass

Laminated glass consists of two or more sheets of glass bonded together with one or more layers of PVB film (polyvinyl butyral). If the glass breaks, PVB films or film keeps the glass fragments.

Depending on the thickness or number of sheets of glass and PVB film number, we have the following benefits: protection against injury, fall protection (the parapets), protection against vandalism and burglary, armed attack protection (bulletproof glass) , protection against noise.

Maximum size we can produce laminated glass are: 1500x 3500 mm.

Insulated Glass

It is the popular name for insulating glazing that between two or more glass sheets close a blade immobile and dry air in order to limit the thermal exchange. Depending on the number, type and thickness of glass panes used as distance or type of gas between them, we have the following benefits: thermal insulation, sound insulation, solar control and safety.

Maximum size that can produce the glass are: 2500x 3500 mm.

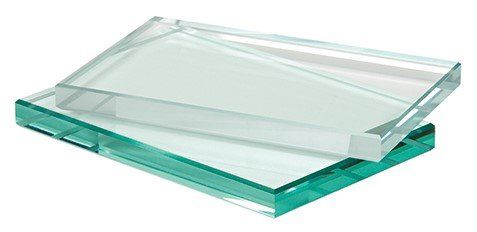

Tempered Glass

Tempered glass or safety glass, as it is called, is produced by heating the glass to a temperature of about 650 degrees Celsius and then cooled suddenly, creating strong compression. The whole process is electronically controlled and the parameters by which this is done fundamentally influence the quality of tempered glass.

By tempering, the mechanical strength of glass is four to five times higher than normal glass and therefore is used in applications where it is necessary to mechanically apply various metal parts on the glass. If it break in pieces it fragments in very small harmless fragments, ensuring the safety and security of people who may come in contact with glass.

Tempered glass has a very wide usage: interior partitions with glass walls, glass doors, shower enclosures, table tops, furniture fittings and fixtures, etc..

Maximum size that can produce tempered glass are: 1500x 3500 mm.

Window Spacer

For a better insulation, the classic aluminum spacers between the glasses can be replaced with a “warm edge” Thermix spacer.

The Thermix ® TX.N ® spacer is a plastic covered by a thin layer of stainless steel, with a thermal conductivity almost 700 times lower than the one of aluminum, and the steel with a conductivity 10 times lower than that of aluminum.